Masterbatch

Our special systems efficiently and cost-effectively meet the specific demands of masterbatch and color batch concentrate manufacturers.

Our processes and systems for the production of masterbatches function seamlessly together to allow optimum results to be achieved.

Conveying, temperature control, filtration, pelletizing or grinding and drying are performed as gently as possible for uncompromising results – no matter whether spherical or cylindrical pellets, micropellets or powders.

The concentrated addition of colored, black & white or function masterbatches produces very good results during the further processing.

Most relevant products for this application

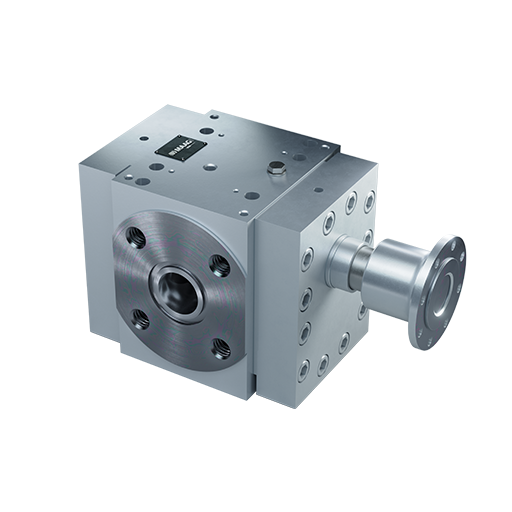

extrex⁶ GU

Extrusion operations require extremely reliable gear pump systems with high output consistency and a configuration to suit each application. The modular design of extrex® gear pumps easily meets the requirements for these diverse applications. The extrex⁶ GU gear pump is a general use design that elevates your process to the next level. With the new… [...]

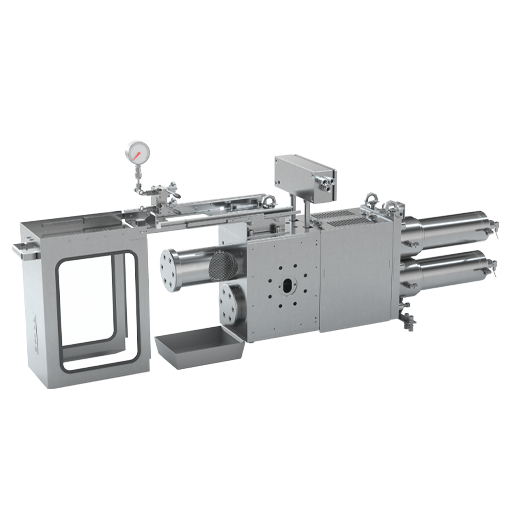

CSC

Continuous CSC screen changers from MAAG with their robust and leak-free operation meet highest quality standards with respect to melt filtration. Due to their constantly improved functionality continuous screen changers from MAAG increase product quality significantly. CSC screen changers are based on the proven double-piston design that operates without any additional seals. Their sturdy construction… [...]

PEARLO®

The PEARLO® underwater pelletizer has been designed to process a wide range of polymers and thermoplastics. PEARLO® works perfectly with our process water system PURO® and pellet dryer CYCLO® and produces first-class spherical pellets. This extremely efficient and flexible system is applied in the production of raw materials, compounds, masterbatches, engineeringg plastics, organic and wood… [...]

MAP

The Manually Adjustable Pelletizer (MAP), a underwater pelletizing application, features a manual adjusting wheel to position the blades against the die plate. This simple blade adjustment design of the underwater pelletizer provides visual blade wear indication and maximum control of blade position. The unique design of the axial advance system replaces the need for a… [...]

EAC

The EAC pelletizer for underwater pelletizing offers fully automated control of blade adjustment, positioning, and monitoring, resulting in maximum blade and die face life. Monitoring and adjustment processes are programmed in the Gala PLC controlled system. An optional integrated blade position measuring system for unterwater pelletizer is available, providing indication of blade position and warning… [...]

PRIMOPlus

The dry cut pelletizers of the PRIMOPlus series are characterised by their robust design. The double-sided bearing of the cutting rotor ensures high stability and precision, resulting in excellent quality of the cylinder pellets. Wear-protected machine parts also ensure a high degree of machine availability and profitability. [...]

eXso dryer

MAAG Gala’s eXso centrifugal dryers are engineered to reduce cost through efficient changeover and higher reliability · Direct drive rotor eliminates belts and pulleys reducing maintenance requirements · 66% more interior access for efficient cleaning and inspection between runs · Optimized rotor to housing ratio for proven drying effectiveness · Interior lighting (optional) and large… [...]